>>>Manual:Click here to open

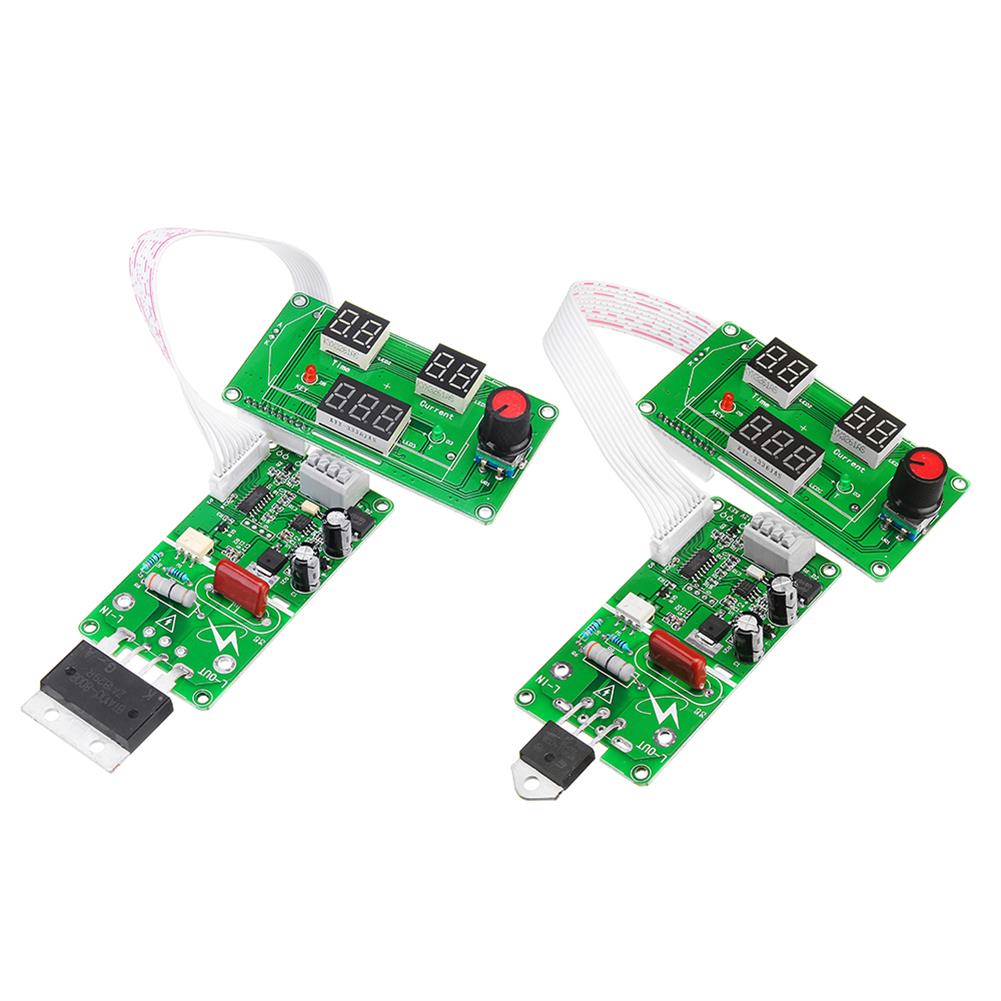

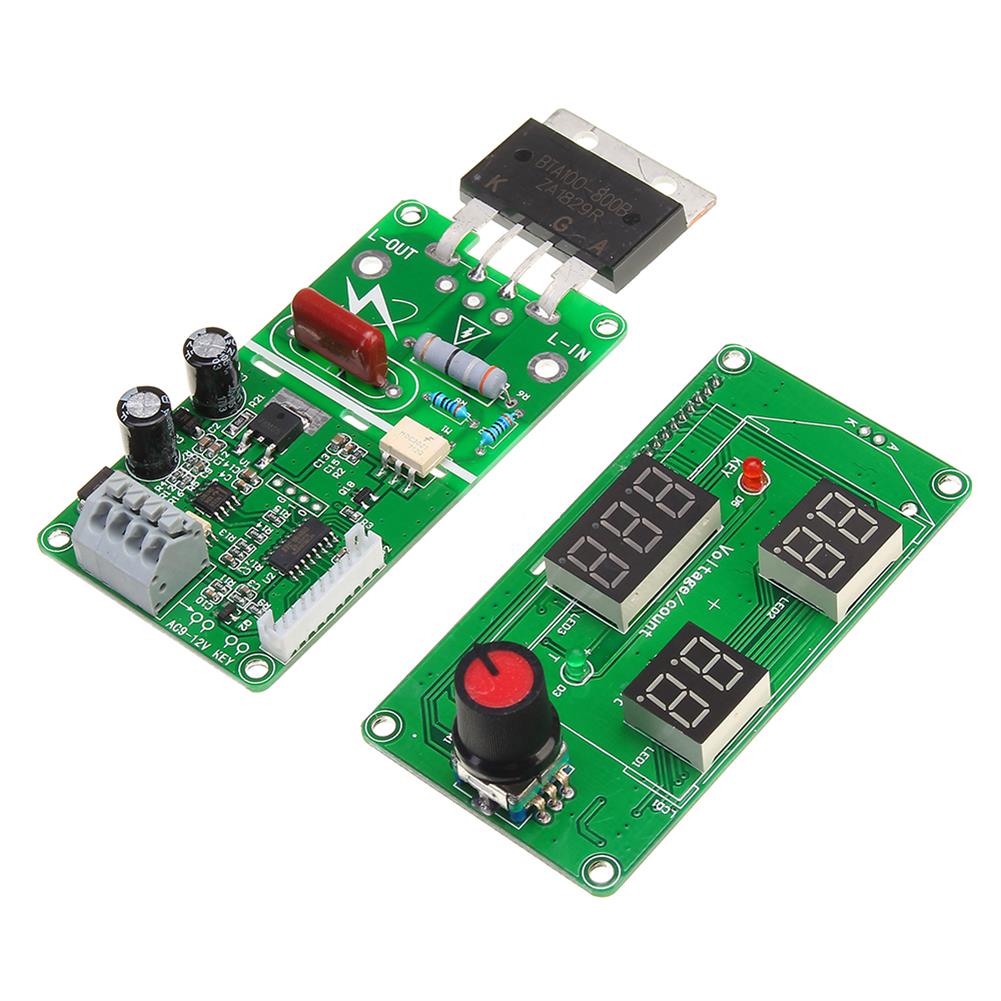

The spot welding control module is developed for DIY or simple battery welding. It is mainly used for single battery or battery group nickel plated sheet welding, such as 18650 lithium battery nickel plating 0.15 and 0.2mm steel sheet, 500W transformer can be welded directly. It is intended to weld other battery materials and different thickness, such as polymer battery electrode without nickel plating, must be combined with sufficient power transformer to weld. This module includes main board and display board, optional 40A and 100A bidirectional silicon control rectifier(SCR), does not include weld transformer, weld pen and other matching tools.

Features

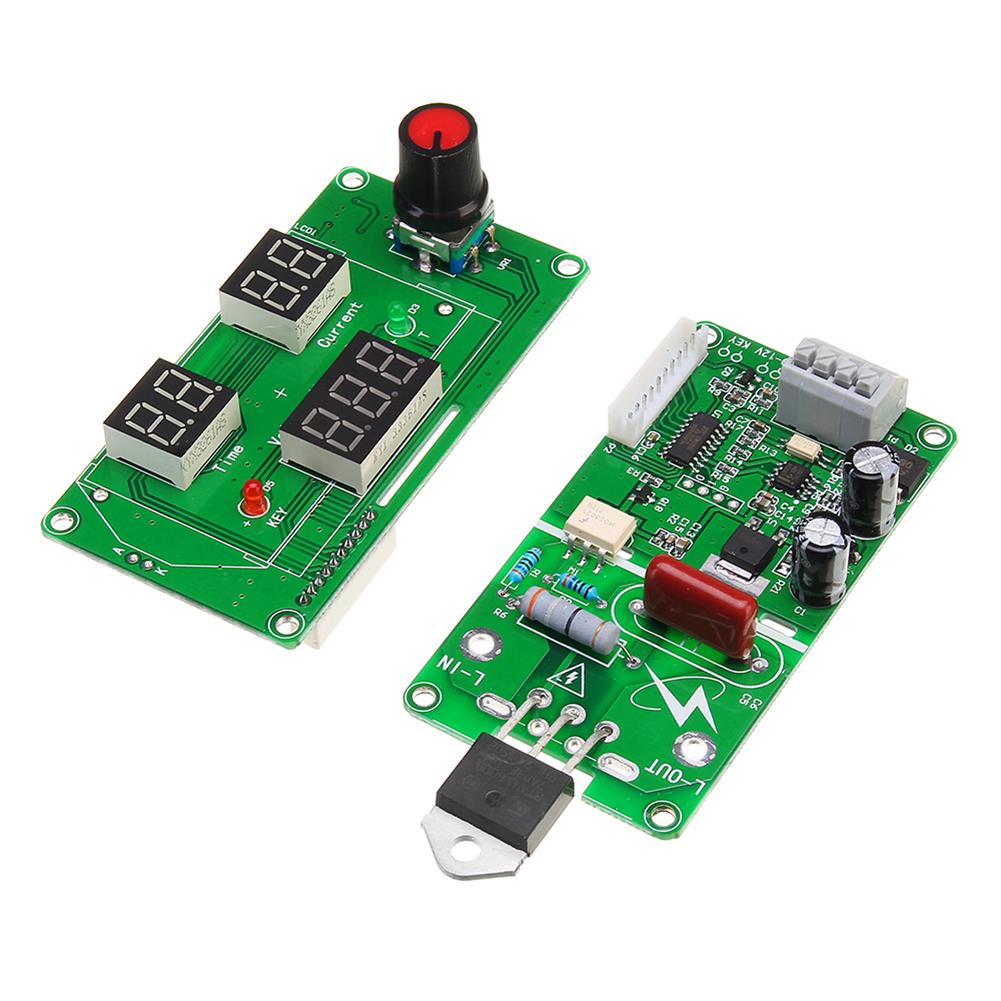

1. The main board and the display panel are separated, and the outer casing can be flexibly assembled.

2. Multi-group data visual display, intuitive operation, convenient, single encoder parameter adjustment can make the operation simple and fast.

3. With grid voltage compensation, the output of compensation can be automatically adjusted according to the change of power supply, and the electric voltage of about 1 second can be displayed when triggered, so that the effective heat of welding is consistent with the welding parameters, and the welding spot is uniform.

4. With 0-9999 welding counting function, with 5 groups of sample storage parameters, can be stored even the electricity power is off, the number of wleding could be seen just by a glance.

5. Time input 0-99 cycle(1 cycle is 20ms, for example, the adjustment value is 50, which is the welding time 1 second.), the stop time between 2 weldings is 0-99 cycles(1 cycle is 20ms, such as interval value 50, It is the interval of 1 second.) adjustable. Welding strength 30%-99% is adjustable.

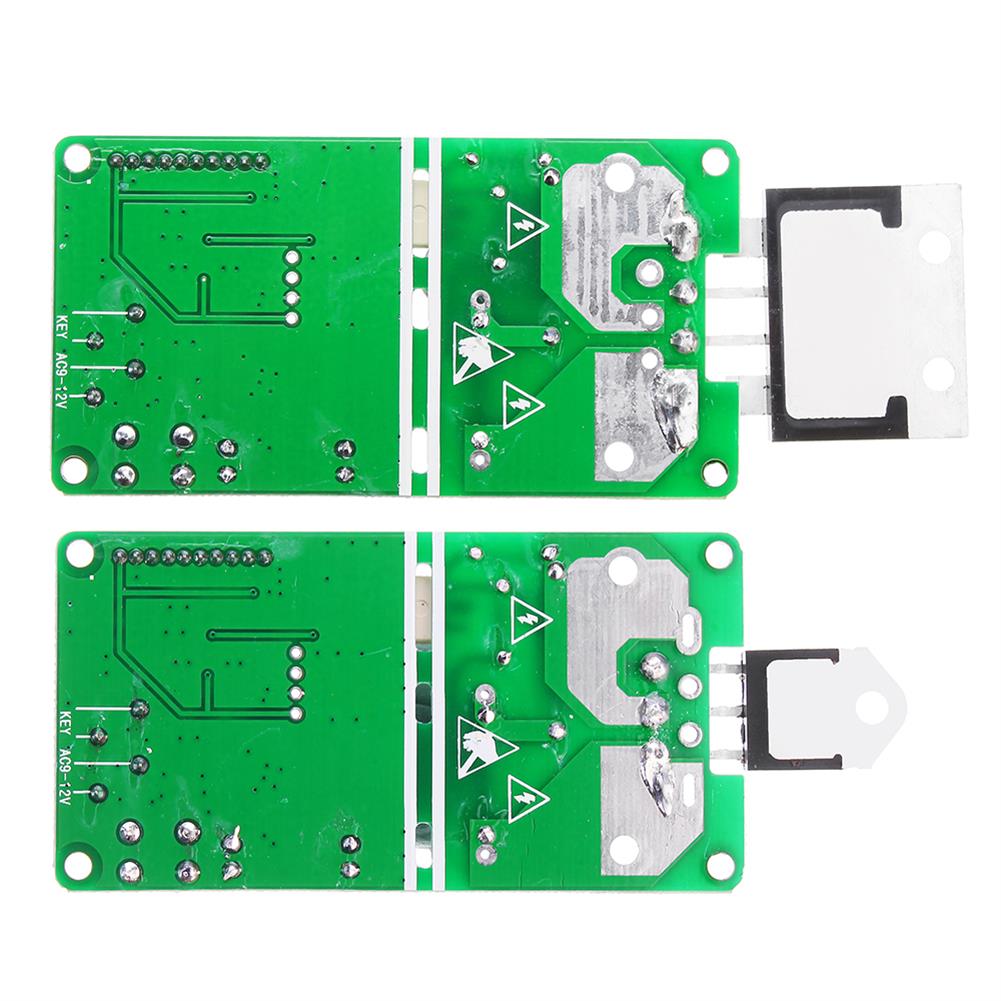

6. The module can isolate the strong and weak electricity by optical coupling, and design a reliable circuit for zero-crossing detection and voltage detection to ensure the accurate phase of silicon control rectifier (SCR), which can be compatible with 40A-100A bidirectional silicon control rectifier(SCR).

9-12 V AC power input(using AC transformer, other such as DC, can cause 0-crossing detection failure, can not trigger.).

7. The power input and external trigger adopt convenient and quick welding free terminal, the external trigger can be diversified, such as normal switch, foot switch, external signal source input, etc., the software has anti-lock stat, triggering to the end of welding, for one round. For example, the pedal switch has been trampled all the time, can only trigger one round.

Scope of Use

1. DIY or simple battery weld development welding.

2. Welding of a single battery or battery pack.

Package Included

1 x Main Board

1 x Display Board

1 x Cable

Additional information

| Weight | 0.1 kg |

|---|

Reviews