Features

– Support PWM signal, analog signal, PPM signal control.

– Rated power supply voltage:5V-40V.

– Limit voltage range:4.8V – 48V.

– The power supply voltage is 12V, 10A continuous current working temperature rise is small and 15 degrees (25°C room temperature ring)

territory).

– Select among the five working modes by the DIP switch.

– Support for high frequency PWM signals

– 100% duty cycle PWM signal input in PWM mode.

– Can withstand large transient currents (180A/10ms) when the DC motor starts and stops.

– In the PPM signal and analog signal control modes, the PWM frequency is 15.5KHz.

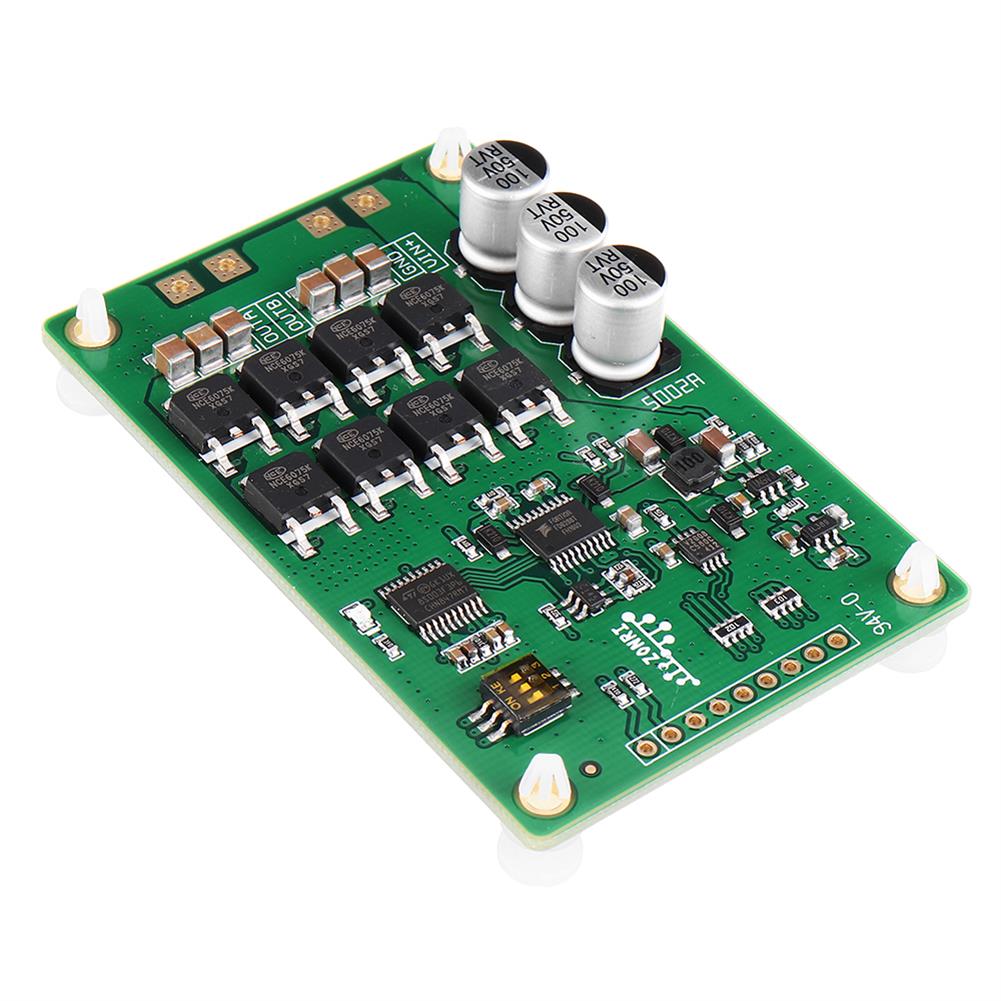

– MOS tube rated parameters are:75A / 60V / NMOS.

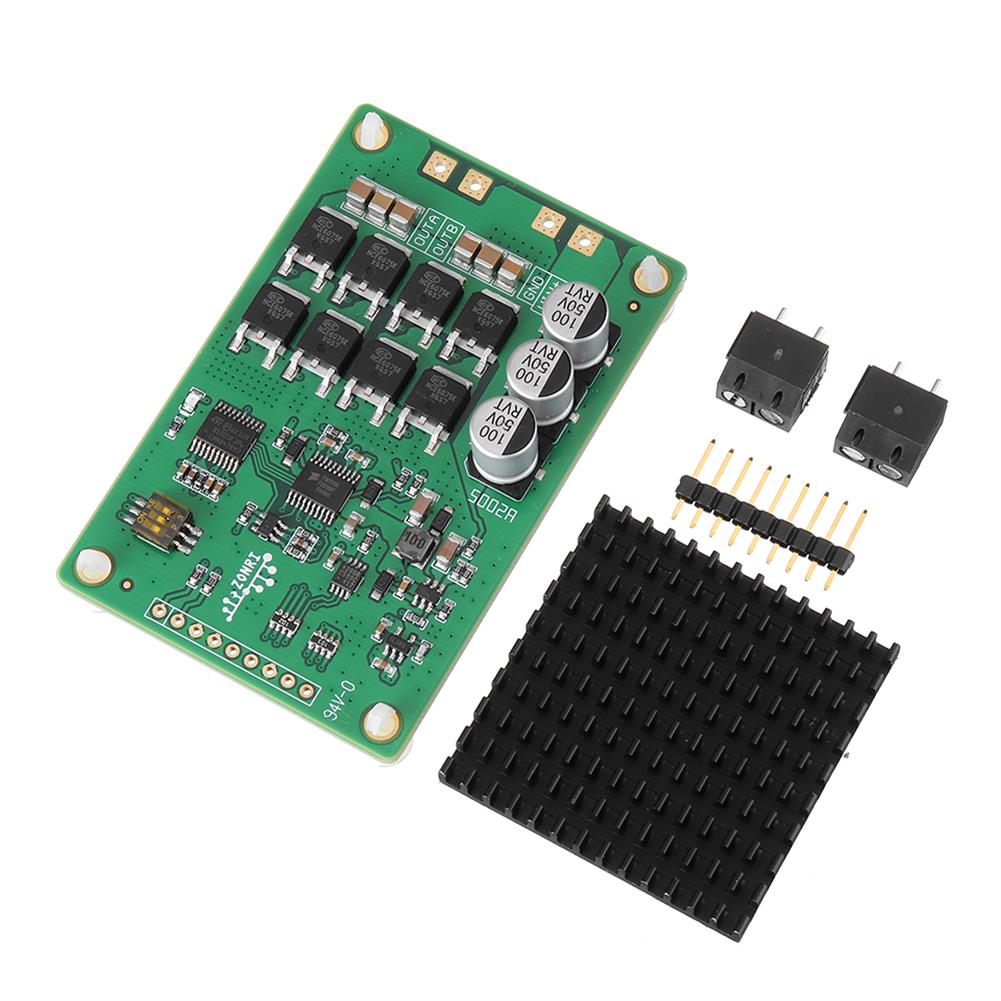

– Four layers of PCB, good thermal and heat dissipation, with adhesive heat sink, users can post according to their needs

Installed.

Questions and Answers

1. Q:How high is the PWM frequency supported by the module

A:In the 25 °C environment, it is recommended that the PWM frequency be no higher than 150KHz to control the switching loss of the MOS transistor. The output waveform and rising edge, falling edge, and input/output delay test waveforms of the driver module at different PWM frequencies are provided below for reference.

2. Q:Will changing the working mode change when the DIP switch is changed during work

A:No, the working mode is the new setting mode after power-on.

3. Q:What model is the MOS tube

Answer:The MOS tube is NCE6075K. Each bridge arm of the H bridge uses two MOSs in parallel.

4. Q:Is the circuit schematic and layout available

A:The schematic and layout of the circuit are not provided by the ZR5002 module.

5. Q:How much power can I drive

A:According to the safe work area icon, the maximum current when the power supply voltage is 23V is 20A, because

This maximum output power is 460W.

6. Q:In PWM mode, when the input signal is 100% duty cycle, is the output duty cycle also 100%

A:No. In PWM mode, the maximum output duty cycle is 99.7% when the input signal duty cycle is 100%. When the input duty cycle is small and 99.7%, the output duty cycle is the same as the input duty cycle.

7. Q:When using the analog control method, how many potentiometers should I use when connecting the potentiometer

A:Potentiometers between 4.7K and 220K can be used.

Package Included

1 x High Power MOS Tube DC Motor Drive Module

Click to download document:MOS Tube DC Motor Drive Module

Additional information

| Weight | 0.065 kg |

|---|

Reviews