Feature

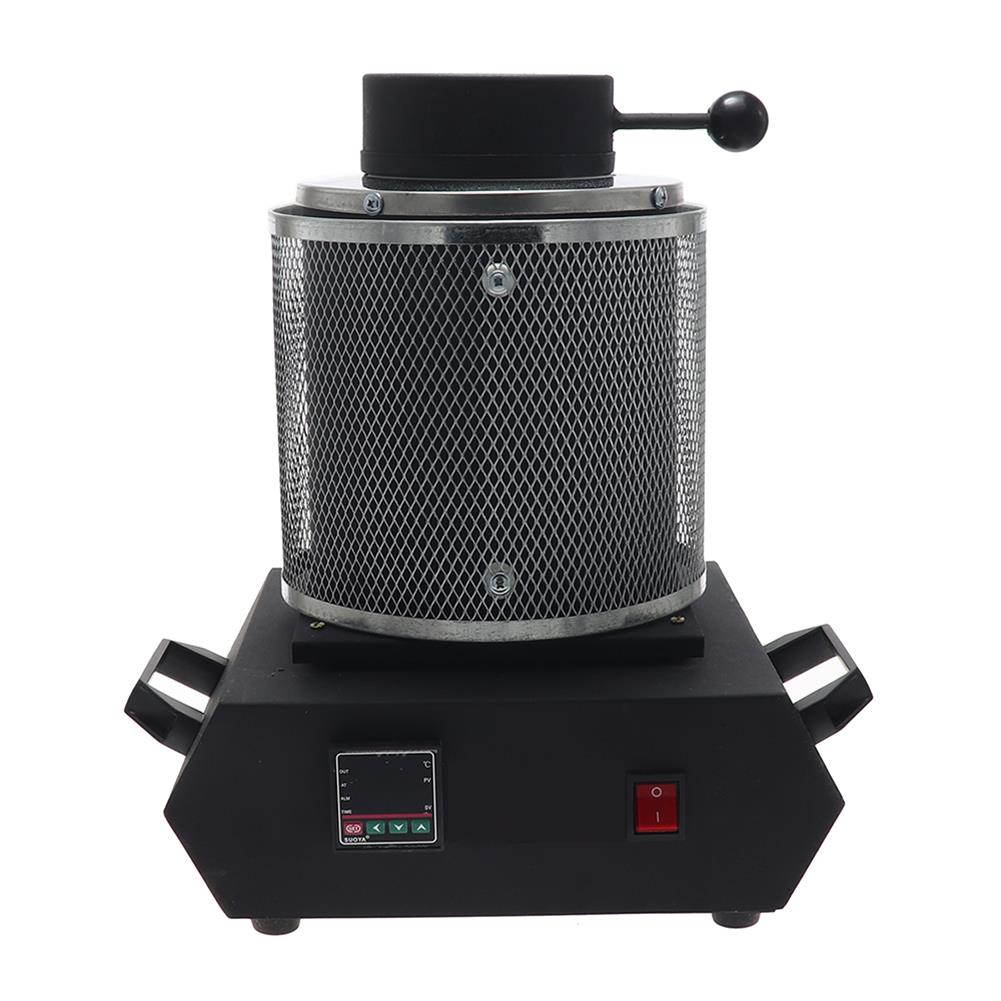

1. High-purity fiber alumina chamber for energy saving – chamber size:60 mm diameter. x 150 mm deep.

2. Precise temperature control, easy-to-read digital display and LED on/off indicator.

3. Single point temperature control (temperature only, no control of heating and cooling rate and residence time).

4. The complete accessory is included and can be used immediately.

5. A heavy-duty graphite crucible with a capacity of 1/2/3KG.

6. Double armrest design, easy to move

7. Metal anti-scald mesh, effectively prevent burns

Specification

ColorBlack

Power input1600W

Power supplyAC220V 50HZ EU Plug

Max.Heating temperature1150℃

Measurement accuracy+5%FS

Dimensions (LxWxH)35x25x38

Shipping dimeensions44x37x31

N/G Weight(kg)11/12

We will send you the plug adapter according to your country.

Operation

1. Plug the device in the power source.

2. Press the ON/OFF button.

3. Set the temperature(smelting temperature)

Press the SET button:SV(= set value)flashes. Every single digit can be set:to select the digit you want to change,press the’

4.The device is starting the heating process.The’ OUT’ light is lit until the temperature reaches the chosen value.

5.As soon as the temperature is reached,the device stops heating.The OUT”light flashes and the temperature remains constant.

6.Cast the metal into the mold and put the crucible back into the heating chamber.

7.Turn the furnace out as soon as the whole quantity of molten metal was used.

Functioning

Control system:the PID

1. The PID module has two functions:to measure and to control the heating.

2. The temperature measurement in the heating coil is made at regular intervals. The information is transmitted to the PID module as current value.If the current value is inferior to the set value,the PID module makes the device heat.If the current value is superior or equal to the set value,the PID module stops the heating.

3. This cycle gets repeated at a 2-second-interall.Therefore,a high grade of precision is ensured.

4. The advantages of the PID module in comparison to a normal thermostat are the flexibility,the efficiency and the precision.

5. The energy consumption can be optimized,and the material fatigue can be compensated.

How does the metal get molten

The PID module controls the power flow to the heating coil(ON/OFF system).When the circuit is closed,the heating coil gets warm and transfers the heat to the crucible which forwards the warmth to the metal(passive heating without direct contact).The metal gets hot and liquid when it reaches its smelting point.

Notice

If you don’ t save the selected value,the device will automatically go back to the main display mode without holding the value which was set after 30 seconds.

Package included

1 x Electric Melting Furnaces

1 x Graphite Crucible

1 x Instruction manual

1 x Plier

1 x Charger

Additional information

| Weight | 12 kg |

|---|

Reviews